Olive oil extraction process…

Our purpose is to provide an outstanding product that delivers ultra premium quality.

After the olives are collected they are delivered to the olive mill for processing.We use open boxes of a maximum of 20 Kg so that the olives do not get crushed.

The sooner olives are pressed after they are picked, the better the oil.

The fruits are milled the same day which means in 3-4 hours after harvesting.

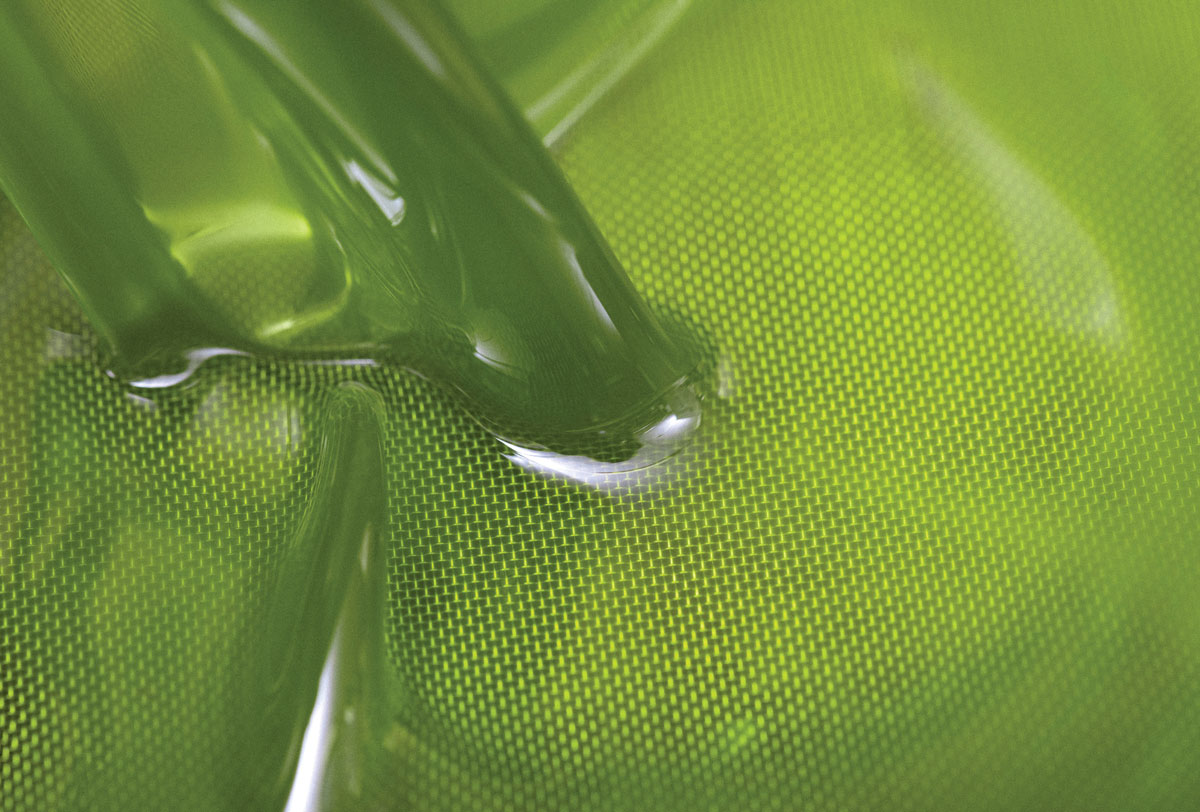

First, olives are separated from the branches, leaves and debris, and then washed with water. Next, they are crushed to form a paste and milled for about 20-25 min with no oxygen and according to the “cold extraction” or “first cold pressing” technique, which is applicable only to extra virgin olive oils obtained at a temperature lower than

22 °C by percolation or centrifugation of the olive paste.

By doing so, we are able to extract and preserve most of the phenolic substances in the oil produced. Our mills have control systems / temperature monitoring in all phases.

Finally the olive oil is stored in stainless steel tanks with no oxygen inside under 17°C.

The final product is bottled in 500 ml & 700 ml premium glass bottles designed for everyday use in the kitchen or on the dining table.

Taste the heritage of our evoo!!